|

Seven Main Technologies (Main

Products)

List of seven main technologies:

-

US

certification, Level 2 technology

-

US certification,

online application technology

-

Microstructure model,

intelligent self-learning and continuous upgrading technology

of the new generation of Level 2

-

Defect early warning system

-

More than 100 sets of

models made of steel and high-end materials

-

More than 100 sets of

lithium battery Smart Manufacturing models

-

More than 100 sets of PPT

in Smart Manufacturing training have been completed

|

number

|

technology

|

explain

|

|

1

|

Defect

early warning system(patent)

|

Predict the future of the site with the historical data of the site, and

establish an extremely accurate model system. In the process of product

processing, when the product has not been completed, it can predict whether

the product being produced is genuine or defective when it becomes a finished

product? If it is defective in the future, in the process of processing, we

should change the parameter combination and even replace the worn parts in

advance, so that the products being processed will be authentic in the future!

In this way, the defective rate can be greatly reduced and the product quality

can be improved! (the system is developed based on BYD production line and

currently controls 6 lithium battery production lines at the same time) [patent

file]

|

2

|

New generation Level 2(patent)

|

Considering the influence of various alloy elements on the processing

parameters in the production process and the performance parameters of

products, such as alloy materials, which are the most popular materials used

this year, comprehensively considering the optimization degree of alloy

materials to improve the performance of materials and the demand for cost

reduction of microalloyed materials, which are used in production, processing

and products, It can be guided by a new generation of Level 2;

Because of the high precision of the new generation of Level 2, its

simulation function can be used in the design of new products to carry out the

trial and error method of new product production, which plays a great guiding

role in the development of new products; The most direct advantage is that in

the production of hard and thin products, when the thickness can reach 5mm,

the accuracy is still very high, but when the thickness of the conventional

Level 2 is less than 8mm, there will be a large number of defective

products due to insufficient accuracy! This technology fills the technical gap

in the world! After the successful application of this technology for more

than a year, an internationally renowned authority (Dr. M. gray, the national

standard setter of the United States, China and India) called for the

development of this technology in the industry! (see also AIST certification

in May 2010 - Level 2) [patent

file]

|

|

3

|

Scheme and development of various intelligent systems

|

(1)The

Level 2 of electric furnace smelting has about 400000 lines of source

code, which adds the temperature prediction model and other models of smelting

process, as well as the optimization model without data loss, and adds the

windows function optimization model

(2)The

Level2 smelting system of refining furnace has about 300000 lines of source

code, added alloying process model, temperature prediction model and other

refining models, as well as optimization models without data loss, and added

windows optimization model

(3)The

Level 2 of continuous casting, about 500000 lines of source code, has

added the temperature prediction model and phase transformation process model

of casting process, as well as the optimization model of no data loss, and

added the windows optimization model

(4)Furnace

coil reversible plate Level 2 (1 million line source program, based

on the original FORTRAN version, the variable definition is reduced from 500

pages to 50 pages, with about 60 variables per page; the microstructure model

is added, the self-learning mode is changed, the continuous upgrading and other

software engineering are added; the main model and related source programs are

changed, etc.)

(5)A

series of models related to the force and energy prediction of the Level2

system are optimized, and the production planning logic of determining the

number of passes is changed; In particular, under the guidance of upgrading

the traditional Level 2 to a new generation of Level 2, bivariate

self-learning can automatically upgrade various model coefficients of

various steel grades (for example, nearly 20000 sets of model coefficients of

150 steel grades have been automatically designed)

(6)Lithium

battery production defect early warning system (simplified version of

Level 2, focusing on the improvement of yield), about 300000 lines of

source programs; Based on the original source program, the characteristics of

continuous casting process model and data stability are added

|

|

4

|

US AIST

Certification: Level 2

Technology

|

AIST

Certification certificate: Project

certificate of "Level2 model for improving product quality and output of

rolling mill"

|

|

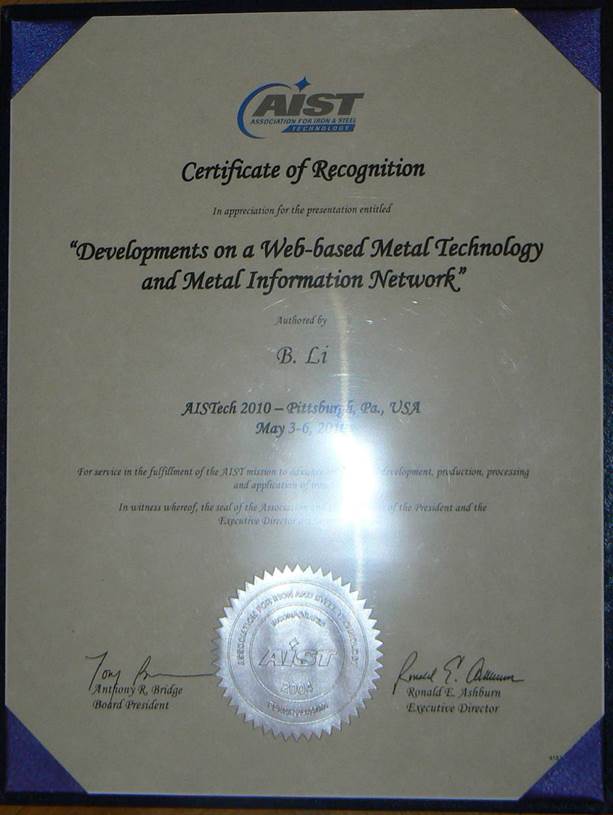

5

|

US AIST

Certification:

Website

Technology

|

AIST

certificate: "web based metal process and metal information network

development" project certificate. Internet based metal technology and metal

information network 50000 page website, dozens of online apps and a large

amount of online data (see www.meta4-0.com), industry 4.0

Metaverse site; Will be used as

verification of defect

early warning system

products; With the help

of more than 200 domain

names, the structure of

more than 200 satellite

websites surrounding a

main website can be

formed.

|

|

6

|

Artificial intelligence

simulation system

|

Based on the

finite element simulation technology, the software system for large

deformation simulation of thermal, mechanical, elastic-plastic deformation

body and elastic tools is used, especially for the simulation of complex

section profile rolling process, including normal full model and simplified

model that can be used for today's machine learning. It can be simulated: (1)

the deformation in the width direction, height direction and length direction

of macro deformation during profile rolling production; (2) The rolling force

and energy demand during profile rolling includes rolling force, rolling

torque, energy demand, etc; (3) The deformation field of deformation at each

position at any time in the rolling process (relative wide deformation,

relative length deformation, relative high deformation); (4) Strain, stress,

temperature, strain rate, dynamic recrystallization, static recrystallization,

grain growth, grain size and mechanical properties of products in each region.

The practical application of the simulation has been comprehensively

verified in the field, including the deformation and force energy at the macro

level, and the verification based on the measured data of the deformation

field when it is completely consistent with the actual section steel rolling

process. For the measurement of deformation field in the process of large

deformation hot rolling of section steel, the mesh is milled on each surface

of complex shape steel with milling cutter, and the steel is cut off on the

surface, the mesh is milled, and then welded together for rolling. At present,

this technology has been transmitted to all section steel production plants in

the world through several major international technology providers, creating a

world precedent for the application of large deformation section steel hot

rolling process simulation technology in factories! This project is a national

project in Germany. The German investment is equivalent to millions of dollars

today. Therefore, the applicant published his first book. The applicant's name

has been posted on the website of his German school for 8 years! [Technical

documentation details]

|

|

7

|

More than 100 sets of Smart Manufacturing training PPT

|

Online free

Smart Manufacturing training has been designed. Recently, more than 100 sets of PPT documents for Smart Manufacturing training have been designed, which are mainly based on the cases

of completed projects, and are used for adding courseware of Smart Manufacturing Specialty in Colleges and technical

Level2 schools. Each set

can be used for teaching for 2 hours. See the websiteMeta4-0.com/training.

[100

sets of courseware PPT]

|

The above table

shows the main products produced by the main technology.

Industry

4.0 Metaverse Company Guide

Resource,

Products,

Defects warning,

Equipment intelligent

Sales

plan,

Q&A,

Work Areas,

Domain Sales

=========

Contact us: Please contact

Linkedin in

www.Linkedin.com/in/intelli, OR scan the figure below to

add Wechat (e.g. myQQfriend); Tel: (+1) 858 898 1288; E-mail BLiMetaverse@Gmail.com. See

Profile of the key consultant.

|